The Best Different Grades of Concrete And Their Usage Reviewed

TweetWhat is Grade of Concrete

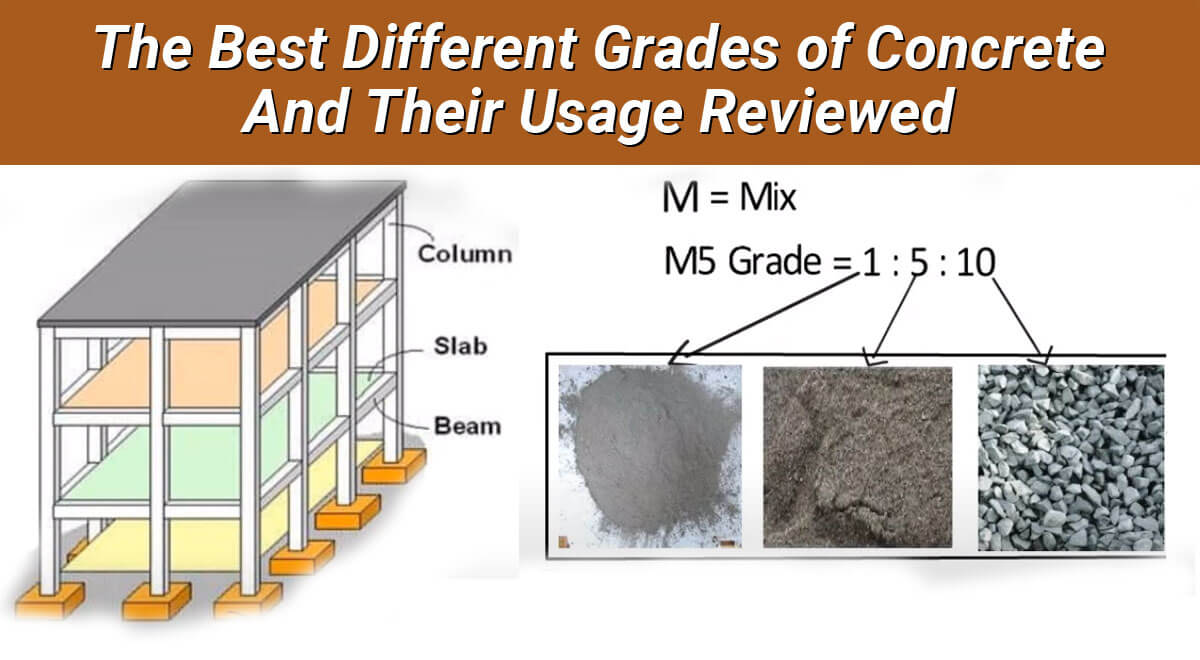

Grade of Concrete is a combination of Portland Cement, water, coarse and fine aggregates. It merges into a hard mass because of chemical reaction called hydration between cement and water. For creating concrete, we use cement, sand aggregate and water which are mixed with a certain ratio and concrete is cast and put in a cube of 150 mm size and put in a water bath for 28 days and later it undergoes a compression test. The compressive test result is known as the Grade of Concrete. In the designation of the concrete mix, the letter M refers to the mix and the number is the specified characteristic strength of 150 mm work cubes at 28 days, expressed in MPa (N/mm²).

In this article we are going to have a detailed understanding about concrete technology and minutely analyse the properties of concrete and its practical application in the construction industry. Though cement plays an important part in making concrete, it serves as an essential element. Cement serves as a glue that keeps everything together. There are five different types of cement depending on what kind of concrete the construction project needs.

- Type I is used for most residential work

- Type II is used in moderate sulphate conditions

- Type III is used in climates where freezing is a risk

- Type IV is used for special orders like industrial placements

- Type V is used in extreme sulphate conditions

For an effective mixture some amount of air entrainment is required. Air entrained cement ensures that excess water has a chance to expand when it moves through the freeze thaw cycle. As a thumb rule the more water you put into the mixture, the mixture will have less strength. There is also probability of shrinkage and cracking if there is an excess amount of water poured into the mixture.

Gravel and Sand makes up about 70 % of the mixture. This high percentage makes the mixture more economical as gravel and sand are both stronger and very much pocket friendly than cement.

Grade of Concrete

Concrete can cast into any shape. Since in the fresh state it is a plastic material, various shapes, sizes and form work can be created with it like rectangular, circular etc.

Numerous types of concrete manufactured these days for construction industries. They have special properties and features which improve the quality of construction as per the requirement. The types of concrete are specified below:

- Normal Grade of Concrete

- Standard Grade of Concrete

- High Strength Concrete Grades

Regular grades of concrete are M15, M20, M25, etc. For plain cement concrete works, generally, M15 uses. For reinforced concrete construction minimum M20 grade of concrete uses.

Grade of a concrete table

| Normal Grade of Concrete | |||

| Concrete Grade | Mix Ratio | Compressive Strength MPa( N/mm?) | PSI |

|---|---|---|---|

| M5 | 1:5:10 | 05 MPa | 725 psi |

| M7.5 | 1: 4: 8 | 7.5 MPa | 1087 psi |

| M10 | 1 : 3: 6 | 10 MPa | 1450 psi |

| M15 | 1:2:4 | 15 MPa | 2175 psi |

| M20 | 1:1.5:3 | 20 MPa | 2900 psi |

| Standard Grade of Concrete | |||

| Concrete Grade | Mix Ratio | Compressive Strength MPa( N/mm?) | PSI |

|---|---|---|---|

| M25 | 1:1:2 | 25 MPa | 3625 psi |

| M30 | Design Mix | 30 MPa | 4350 psi |

M35 |

Design Mix | 5075 psi | |

| M40 | Design Mix | 40 MPa | 5800 psi |

| M45 | Design Mix | 45 MPa | 6525 psi |

| High Strength Concrete Grades | |||

| Concrete Grade | Mix Ratio | Compressive Strength MPa( N/mm?) | PSI |

|---|---|---|---|

| M50 | Design Mix | 50 MPa | 7250 psi |

| M55 | Design Mix | 55 MPa | 7975 psi |

| M60 | Design Mix | 60 MPa | 8700 psi |

| M65 | Design Mix | 65 MPa | 9425 psi |

As per BS 8500-2 British/European standards The grade of concrete is denoted as C10, C15, C20,C25, etc., 'C' which means 'Concrete Strength class' and number behind C refers to characteristic Compressive strength of Concrete in N/mm2 @ 28 days when tested with the 15cm dia& 30cm height cylinder in direct compression test

The grade of concrete is also denoted as C16/20, C20/25, C25/30, etc., which means Concrete Strength Class (C) the number behind C refers to Compressive strength of Concrete in N/mm2 when tested with Cylinder / Cube.

Types of Concrete

There are different variants of Concrete used in Construction Projects.The top most common concrete used frequently is mentioned below and let us see their usage too.

- Reinforced Concrete

- Lightweight Concrete

- High-Strength Concrete

- High-Performance Concrete

- Precast Concrete

Reinforced Concrete

As the name suggest, reinforced concrete is used in conjunction with bars, fibres or other materials to improve the tensile strength of the Concrete.These materials mostly rebar are more pliable than concrete and pass those characteristics on to the concrete structure to the whole.Usually most of the concrete applications used some kind of reinforcement.

Lightweight Concrete

Made from pumice rock this concrete is less structural and more used as protection for metal building materials or as non-load bearing concrete walls. This type of concrete is mainly used for insulation in water pipes within the facility and provides fire proofing as well.

High Density Concrete

This type of Concrete when the composites of the concrete structure need to be extra secured. Iron or barytes are used as a heavy aggregate. This concrete can be a bit thinner than plain concrete.

Precast Concrete

Precast Concrete is made off -site using a mould. It is generally poured into a wooden or steel mould with wire mesh or rebar. This mould may also have prestressed cable, if needed.

Final Thoughts

For every unique Construction Project, it requires concrete with some kind of tensile strength. In today's dynamic world all we can say is that Concrete's unparalleled durability, complete recyclability with industry innovations like low carbon Portland limestone cement carbonated concrete or concrete cured with CO2 rather than water, all contribute to making it the lowest carbon building.

Taking concrete into a new dimension, concrete's ability to store energy helps to cool the interior temperature of the house. It also enhances, hydronic heating and cooling systems, concrete enables energy efficiency improvements of 70% over the Model National Energy Code for Buildings. Concrete is typically manufactured within 160 kilometres of a project site, using local resources. This greatly minimizes shipping and pollution and makes a significant contribution to the local economy. Thus we can rightly say that concrete is that product that is used more than any other man made product in the world.