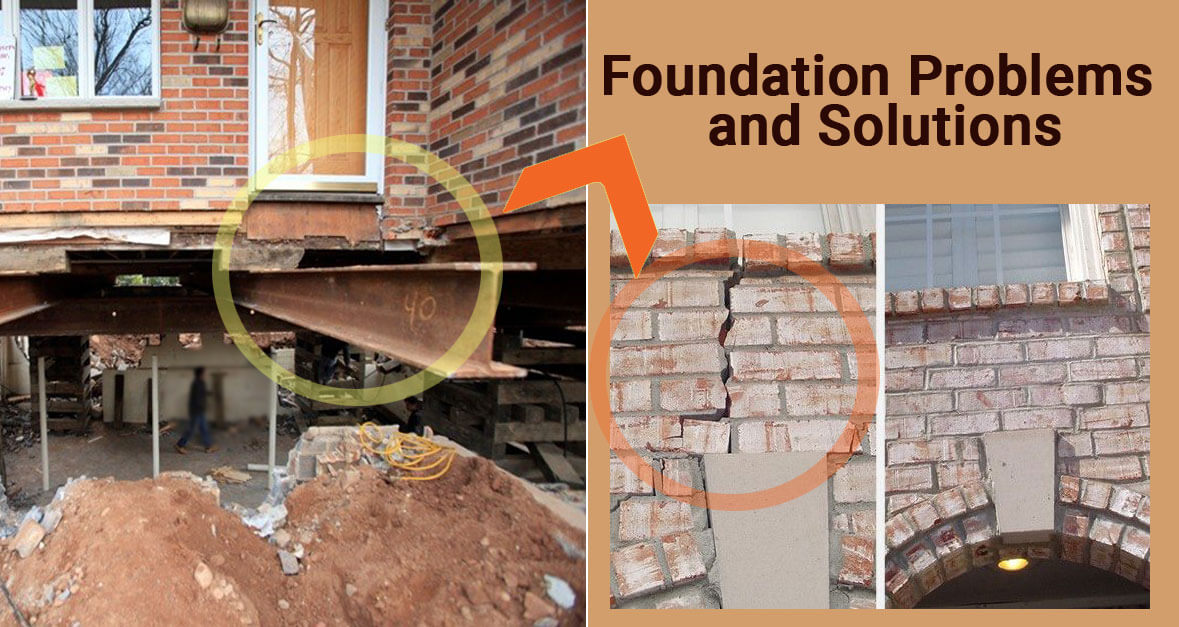

Foundation Problems and Solutions

TweetGiven below are the explanations which can guide you to seek out the problems in foundation.

When the ground separates from its floor resulting in bumpy or descending floor,if you discover there are cracks within the bricks or blocks of a wall, just in case of cracks within the ceiling decorations or moldings, once you can spot a swelling exposure of a neighborhood of wall or noticeable split or separation during a continuous wall, when there's an overlapping of cracked wall parts (this crack is typically seen on wall which lies between the door frame and ceiling), when there are cracks in steps / floor / floor tiles, cases during which you can't open or close the door / window properly and separation between door/ framework & wall.

NOW LET'S CONSIDER WHAT REASONS MAY CAUSE FOUNDATION DISTRESS?

Foundation distress are often caused by contents which is present within the soil, also can be caused by compression or expansion in soil, improperly compacted soil, it are often the results of natural disasters like earth quake, sudden exertion of artificial forces or poor maintenance can lead the inspiration structure to repair.

Also, with uneven movement among the soil layer which takes place after the settlement of foundation structure also can cause the damages as, the inspiration structure rests on soil layer.

Now let's land on the most a part of the article that's sorts of foundation repairs.

SEALANTS IN FOUNDATION REPAIR

Even though regular maintenance is inspired , the straightforward or minor cracks are often treated with masonry patches or sealants.

For minor cracks these are sealers which are utilized in the development industry- Portland cement ( which may be a lot like cement mortar and may set in no time with respective to time) or epoxy (which is analogous to stick and may be found during a sort of viscosity on use various width of cracks) or polyurethane ( it's an honest sealer and may set fast). This step must only be taken just in case of minor cracks.

SLAB JACKING OR MUD JACKING IN FOUNDATION REPAIR

Previously the sunken slab which is raised by filling mud under the slab or maybe by filling concrete mixture under the slab using hydraulic pumps. In recent time, the hydraulic ram is replaced by a trailer which consists of polyurethane system.

This trailer can carry the quantity of cube required, along side portable hydraulic slab-raising pump, also with cement mixer and time duration for the cleaning process of the machine which is eliminated within the new process as there's no requirement for heavy equipment for instance cement mixer and thus requires less time to wash the equipment.

What happens within the slab jacking process by concrete mixture or mud mixture is that the mixture is poured into a cement mixer wherein water and additives are added. To the portable pump the ultimate mixture is shifted after which the pump are often moved to the specified location.

Ultimately, using the hoses the mixture are often pumped into the drilled holes. The mixture must be refilledwhen the pump is empty. variety of steps are often eliminated in slab jacking process by polyurethane. Here, the sole thing that's required is that the injecting of the froth into the holes when needed. Kept within the trailer is that the two liquids which may react to urge the specified foam are stored apart.

The injecting gun which one end is attached to the hose is inserted into a hole to pump out the froth this takes place after the holes are drilled. Within a touch period of your time the froth expands its volume by nearly 25 times and it then sets to a rigid material. The polyfoam slab jacking is small costlierthan to mud or concrete slab jacking.

A more usual process is that the slab jacking which is employed to regain the position of sunken concrete by pumping cement mixture & other additives. It must be noted that slab jacking isn't an easy task because it needs professionally specialized equipment, knowledge and persons. With the usage of portable equipment like pump and hoses the cement mixture will then be ready to pump into the tactically drilled holes on the prevailing concrete structure.

ADVANTAGES OF SLAB JACKING

The old base is strengthened by the new concrete mixture. as compared to the necessity to exchange the entire structure the value required for slab jacking is low. The place where slab jacking has been done are often used within hours. there's no wastage and noise pollution as compared to the replacement of a replacement structure.

Given any weather this method is extremely suitable. No cleaning of space is required as this method can never ruin the place when compare to the remainder . there's no chance for colour change within the structure thanks to the very fact that the new concrete mixture spreads beneath the old slab layer.

The problems involved during this method is, excessively pumped concrete mixture or thin concrete mixture may lift the structure on a wrong place or tends to make new cracks or enlarges the old cracks.

PIERING OR PILING IN FOUNDATION REPAIR

In this technique, steel or concrete piers is employed to resettle the inspiration . There lies a touch difference between piering and piling technique. By just excavation piering are often done whereas piling must be done by driven piles into the bottom . Some sorts of piering or piling includes- concrete pressed piling, steel pressed piling and bell bottom piering.

STEEL PRESSED PILING

IPiling piers and Piering helical piers are the 2 ways to figure during this category. Piling piers is galvanized or coated steel pipes are driven into the bottom with the assistance of hydraulic pump and piering helical piers is galvanized or coated screw piles with steel shafts are wont to here.

A trench should be dug round the foundation and when the steel pile reached an appropriate stable point, the hydraulic jack is employed for bring the inspiration back to its normal position, this process must be followed for installation. Ultimately, the steel shaft attached to the pile is fixed to the inspiration by bolting or welding.

ADVANTAGES OF STEEL PRESSED PILING

The advantages include how the steel piers can press deeply into the soil and may therefore provide a firm attachment to the soil. The installation cost of steel piers is low. in comparison to concrete piers the steel piers can withstand more heavy weights.

CONCRETE PRESSED PILING

First you've got to drill holes on the structure which is in need of repair to a deep depth. After which subsequent step is to fill the opening with reinforcement and concrete. sometimes precast concrete piles are used, during which case you want to never use any reinforcement.

ADVANTAGES OF CONCRETE PRESSED PILING

Low in cost

Heavy equipment isn't required

Tactical skills not much required as within the case of slab jacking method.

BELL BOTTOM PIERS

Here a shaft within the shape of bell drilled in to the inspiration structure then the space after the belled shaft is removed will fill with reinforcement and concrete.

ADVANTAGES OF BELL BOTTOM PIERS

Provides good strength

Due to the form of rock bottom , movement is prevented within the piers within soil layer.

Curing of piers before completion of project is required when as compared to the remainder.