How to Conduct Slump Test for Fresh Concrete?

Tweet fdsfdsfdsgBefore placing the concrete within the site, it's important to live the properties of fresh concrete. Tests are carried so on confirm that the properties which are required are present within the fresh concrete which successively influences the strength and sturdiness of the structures.

Since different concretes are utilized in achieving different concrete mixtures. As a results of which the properties of fresh concrete depend highly on the type of concrete that's to be utilized in the structure. the foremost important properties of fresh concrete are:

- Workability

- Temperature

- Setting

- Segregation of the concrete

- Plastic shrinkage on the concrete

- Thermal shrinkage and thermal expansion on the concrete

- Water cement ratio

Workability is one among the foremost important properties of fresh concrete for all types of concrete. Workability is that the ability to figure easily with a concrete where it are often poured into the mold and compacted to make the specified shape with none quite segregation or defects and with the specified strength and lifespan. Defects and cracks arise when there's a high amount of moisture present which is quite that designed thanks to thermal shrinkage.

The workability of concrete are often acknowledged using these three tests- slump test, compacting factor test and V-B test. The slump test is typically favored within the site so understand the consistency of the fresh concrete as performing this test is extremely low cost and requires low labor skills. The slump test is performed when the concrete is completely fresh at the location as soon because the concrete truck arrives with it.

It is in accordance with ASTM C143 in US and EN 12350-2 in Europe that the slump test is performed. Other countries have their own defined slump test procedure consistent with their own standards.

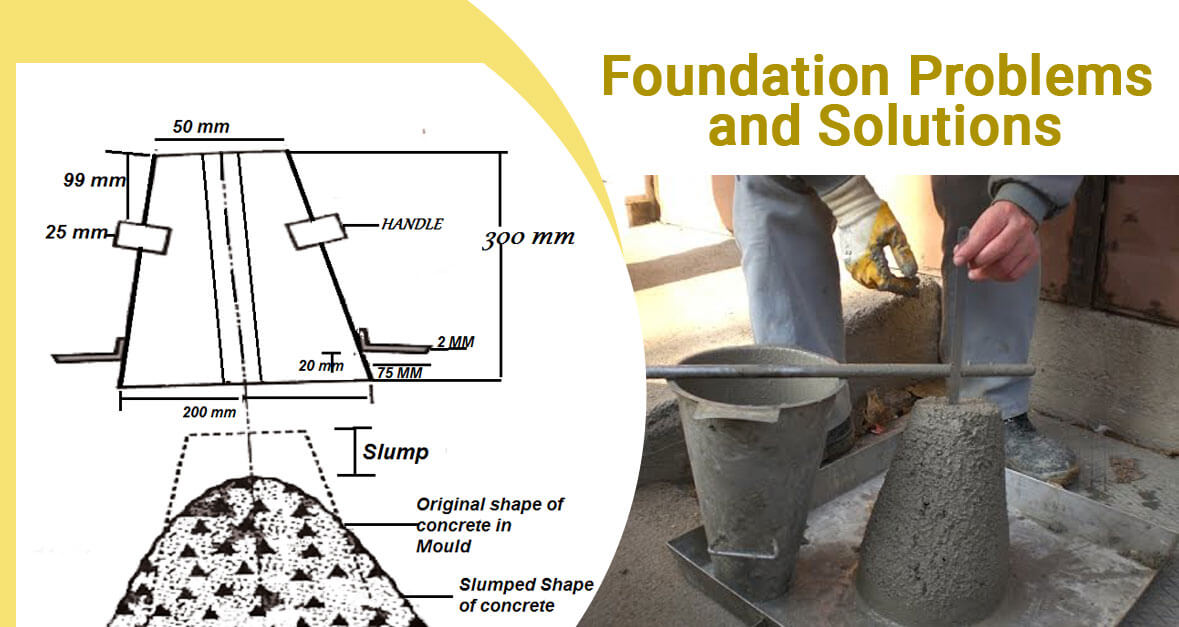

The General Process for Slump Test

The slump cone must be kept on a clean tray after cleaning it. After which the concrete is poured into the cone in three layers where each layer should be ready to compact for 25 times employing a tamping rod. After the highest level is filled, the highest surface must be smoothened then the cone should be lifted within the vertical direction.

The concrete is then left to slump, after the slumping process the slump is measured. Depending upon the concrete mixture the slump utilized in site will differ with a tolerance of 20mm or of appropriate values.