What are 4D and smart materials? What are their collaborative uses?

TweetIntroduction

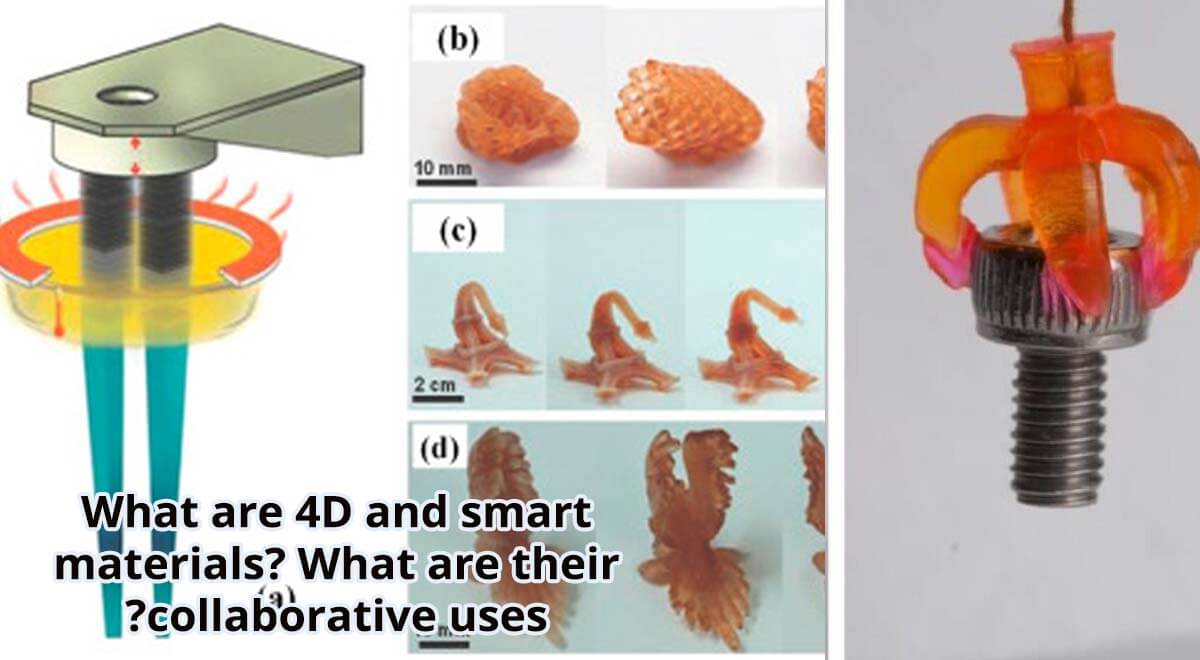

We learn more and more about brand-new 4D printing efforts. The 4D printing method uses the same printing process as 3D printing; however, the material used in these two manufacturing processes differs, making it possible to produce 4D printed things. These materials are referred to as smart materials.

If 3D printing has already utterly revolutionised the industrial sector, 4D printing has the potential to do the same. In fact, this method might make it possible to build more than just static structures.

What is the definition of smart materials?

Smart materials are those that exhibit one or more qualities that respond to environmental stimuli. They may also be referred to as responsive materials. When exposed to hot water, pressure, chemicals, light, or heat, these things can alter shape or behaviour.

You might even be able to self-assemble these smart materials as soon as you touch them. It is possible for such an object to transform into a brand new shape when it is stimulated with an external stimulus since these materials are reacting to their physical environment when faced with an external stimulus.

What do you mean by 4D printing?

During the process of 4D printing, a 3D printed object undergoes a change in structure as a result of external energy sources such as temperature, light, and other environmental factors which influence the object's morphology.

There is a technology that is part of the self-assembly lab at MIT that is working on this project. In order to imagine how construction, manufacturing, product assembly, and performance might be reimagined, the focus of this project will be to combine technology and design in order to develop self-assembling and programmable material technologies.

Workflow of 4D Printing

There is a technology called 4D printing which involves the use of commercial 3D printers, such as the Polyjet 3D printer. One of the inputs to the system is the smart material, which can either be a hydrogel or a shape memory polymer.

Taking advantage of their thermomechanical properties, as well as other material properties, smart materials are able to change shape and are able to differentiate themselves from the common 3D printing materials due to their shape changing features.

Objects that have been created using 3D Printing technology, on the other hand, exhibit rigidity due to their complexity. As a result, the 3D printed objects will retain their 3D shape after they have been printed and they will therefore remain functional.

4D printing with smart materials with their uses

The application of 4D printing can be found in a variety of industries, including medicine and engineering. In spite of the fact that there is still a lot of research going into this technology, we are still trying to see how useful it can be in the most demanding sectors.

Improvement of the devices that provide energyA possible application for shape memory materials would be in the field of solar panels that might be used as sensors to detect the sun's presence. If solar panels were designed in such a way, they could completely rotate towards the right direction on their own. The combination of this technology with robotics could lead to a solar panel that is totally optimized to get the most amount of solar energy from the sun.

Smart materials for construction purposes

There is actually a good possibility of creating a structure that can grow, self-repair, and adapt fairly quickly to the environment with the mix of traditional materials with smart materials. It is precisely this type of research that DARPA's Engineered Living Materials (ELM) program is aimed at doing utilizing living biomaterials in architecture and construction.

Automotive or Aeronautics

In addition to using a 4D-related smart material that reacts to the temperature of a jet engine to cool it, People have also begun using a wing that changes shape according to aerodynamic conditions in order to decrease air resistance. Getting devices adapted to automatically adjust to external conditions is a major asset for many different industries.

Medical Usage

In the medical industry, 3D printing is actually quite beneficial, and there are also recent advancements in bioprinting technology that are also helping. Shape memory polymers can be introduced into the body and react to changes in the body and stimulations within the body when they are inserted inside of the body. It is true that this could enable the creation of brand new antibiotics that would be able to react to changes in the body temperature, for example

Fashion Purposes

Fashion could also be transformed as a result of 4D printing. In order to study the potential applications of 4D technologies, the Self-Assembly Printing Lab at MIT has been established.

Among the ideas that have been proposed is that clothing can be changed depending on the weather or the activity that is taking place.

When you start running, for instance, the shape of your shoes could change in order to provide you with better comfort and adequate amortization when you run.

Automatic Assembly Furniture

The limitations of 3D printing furniture are related to the size of the printer, but the possibilities of 4D printing could make it possible to simply print a flat board that can be curved into a chair with just a little bit of water or light added to it.