Importance Of Shear Wall In High Rise Building

TweetWhat is Shear Wall

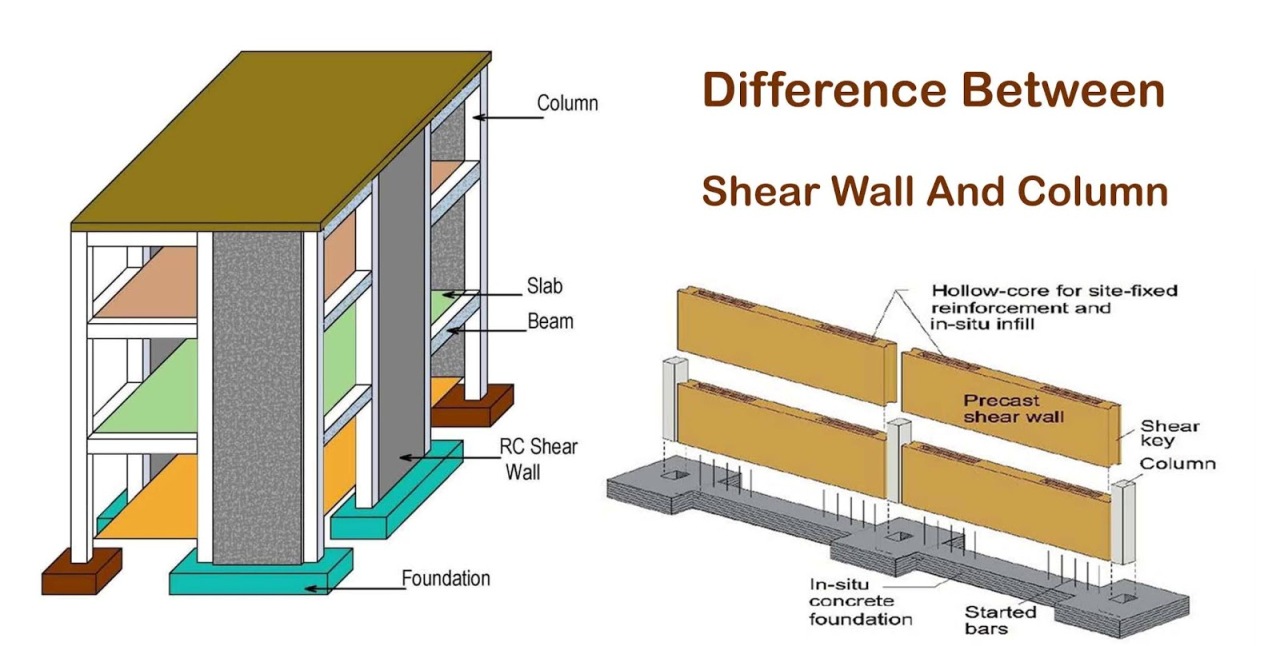

Shear Wall is a structural member used to resist the lateral forces of wind and seismic activity. We all know that columns and walls keep the building standing up, It is the shear wall that resists the loads due to Cantilever Action.

This article will give detailed information about the functionalities of the Shear wall and its location in high rise buildings.

Purpose of Shear Wall

To understand the dynamics of shear wall in an easy way , let us consider the shear wall as a wooden square with four edges essentially two columns and two beams. This frame actually supports the compression weight from above , as any load put on the upper beam is transported through the columns to the base of the square.

Putting too much pressure on it’s sides as a lateral force and the square will twist and collapse on itself unless it is braced by supports.

The support implemented by shear walls craft a design obstacle for engineers and architects. Remember the taller the building the greater is the need of Internal shear wall and a lateral force resisting system.

Position of Shear Wall

The shape and plan position of the shear wall influences the behavior of the structure considerably. Structurally, the best position for the shear walls is in the center of each half of the building. This is rarely practical, since it also utilizes the space a lot, so they are positioned at the ends. It is better to use walls with no openings in them. So, usually, the walls around lift shafts and stairwells are used. Also, walls on the sides of buildings that have no windows can be used.

Generally the ideal location for shear wall in high rise building is on the center of each half of a building. Shear walls must be built symmetrically around the building’s central axis.

Types of Shear Wall

Shear walls are classified into the following types .

1. Concrete Shear wall

This typical shear wall consists of the reinforcements and concrete slab. The wall thickness of Reinforced Cement Concrete varies from 150 mm to 400 mm . The Shear wall starts from Building foundation and end to the Building Top.Concrete is poured into the formworks and removes after the standard time of formwork removal.

2. Steel Shear Wall

This type of Shear wall consists of Steel Plate Walls bounded by the columns .It is mainly used in High rise buildings.The boundary column and the steel plate will act as the vertical plate girder. In here the steel plate acts as the web of the vertical plate girder whereas the columns act as flanges. After the reinforced foundation is finished , the shear wall ‘Anket Bolts’ should be installed in to the reinforced foundation.Then the concrete is poured and the column plates should be installed and level it by grout.

3. Plywood Shear Wall

This is the most common form of shear wall in US buildings. The wood frame with vertical studs alone is subject to deformation and collapse, and so the frame is covered in sheathing, typically plywood or oriented strand board (OSB).Thus it assured rigidity under lateral forces.

4. Moment Frame Shear Wall

Moment Frame Shear Wall are created to resist the lateral loads and improve the rigidity of the structural frame , by making connections. By creating moment connections, the spots where the beams and columns come together are kept at 90 degrees. This provides rigidity to the building, creating a resistance to the lateral loads. These connections can be just on one bay (on each floor), so one floor’s moment connections can be removed to show that that floor will collapse with no lateral resisting system, even though the other floors stayed rigid.

5. RC Hollow concrete Block Masonary Walls.

These walls are constructed by reinforcing the hollow concrete block masonry, by taking advantage of hollow spaces and shapes of the hollow blocks. It requires continuous steel rods (reinforcement) both in the vertical and horizontal directions at structurally critical locations of the wall panels, packed with the fresh grout concrete in the hollow spaces of masonry blocks.

Shear Wall and It’s Forces

Shear Wall Mainly resist two types of Forces

Shear Force

A shear force is a force applied perpendicular to a surface,opposing the offset force acting in an opposite direction. Defining it in simple terms one part of the surface is pushed in one direction, while another part of the surface is pushed in the opposite direction.

Uplift Force

An uplift force is any upward pressure applied to a shear Wall that has the potential to raise it relative to it’s surroundings. This kind of forces can be a result of presure from the ground below wind, surface water and so on.

Advantages of Shear wall.

There are many benefits of Constructing Shear Wall . The advantages of Shear Wall are mentioned below:

- In the direction of orientation these walls provide large strength and stiffness.

- It reduces the lateral sway

- These walls are easy in implementation and construction.

- It provides strength and rigidity in the direction of Alignment.

- It minimises the damages to structural and non structural elements

- These walls requires less construction time

- Typicall these walls have have enough well-distributed reinforcements.

- These are lightweight and thinner walls

Disadvantages of Shear Wall

- Shear Walls are very difficult to construct

- The appearance is not so eye catchy , it has a flimsy appearance

- With the buckling of web plates a large banging sound comes.

- It has low stiffness and energy dissipation capacity.

- It requires a huge moments connection.

Application of Shear Wall

We Construct these type of walls to resist the vertical loads /gravity loads and lateral loads.It is structurally combined with the roof of the floor. Due to air drag these walls have to resist uplift forces. The Structural element of the shear wall is extra stable.If we consider the Reinforced Cement Concrete and Shear wall , the supporting area of Shear wall is always high in comparison with Reinforced Cement Concrete .

Design Consideration taken while building a Shear Wall.

There are certain consideration which needs to be taken while building shear wall

- The thickness of the wall should be between 150 mm to 400 mm

- The diameter of the bar is is between 1/10 of the wall thickness.

- Minimum reinforcement is 0.25% of the gross area of the section.

Final Thoughts

Shear Wall is the most effective component in building construction as it resist the lateral forces during the earthquake.We can minimize the force of the high and turbulent winds by damaging shear wall due to the impact of lateral forces caused by earthquakes. Steel space shear walls occupy less space than Reinforced Cement Concrete Shear Wall. In developing countries like India ,Bangladesh, Pakistan etc. shear wall are the backbone of Construction Industry.Arrangement of shear walls have influence on material consumption and concrete consumption and steel.

Shear walls are more effective in High rise building than Low rise building.Finally we can say for accomodatioon of large number of People in a small area structure shear walls are considered most useful.