Types of Batching of Concrete

TweetConcrete may be a versatile, durable, sustainable, economical material, and world's most generally used construction material. The proportion of concrete ingredients should accurately measure to form the superb quality of concrete. One can accurately measure the concrete ingredients by completing the batching process.

Batching is that the process where the number or material proportions like cement, aggregates, water, etc. Those are measured supported either weight or volume to organize the concrete mix.

Proper Batching improves the workability of concrete by reducing the segregation or bleeding in concrete. It helps to urge a smooth surface of the concrete. It also increases the development speed and minimizes the wastage of concrete ingredients. Hence, batching of concrete is an important process while making concrete.

To form durable, sustainable, and economical concrete, one should have administered the concrete mix design (CMD). The scientific and systematic process of selecting an economically relative proportion of varied ingredients from the available material give cohesive concrete of the specified workability at the new stage with desired strength and sturdiness within the hardened stages is understood as Concrete mix design (CMD).

Once concrete mix design carries out, the primary task is batching concrete materials like cement, aggregates, admixture, etc. The concrete batching happened by measuring and mixing required concrete ingredients either by weight or volume as per the combination design.

Once materials batch, they're introduced into a concrete mixture to supply a consistent and homogeneous concrete mix. within the cement mixer machine, cement, aggregates (sand or gravel), and water is added to make the concrete. The mixer machine not only achieves the concretes mix uniformity but also discharges it without disturbing that uniformity. The mechanism that mixes concrete knows the "mechanical cement mixer " or just concrete mixer.

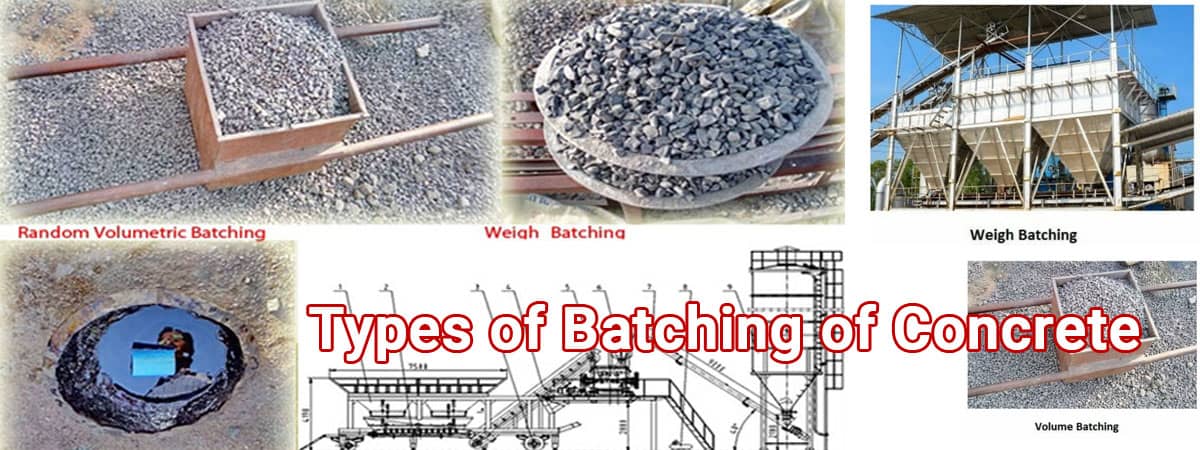

Random Volumetric Batching of Concrete Ingredients

Random volumetric batching may be a batching process that can't control the proportion of concrete ingredients like cement, aggregates, water, etc. It leads to errors, and ultimately, the concrete might not achieves its designed strength.

In random volumetric batching, the proportion of concrete ingredients cannot control thanks to the dimensions and shape of containers. This practice is unscientific, crude and will never be allowed even for alittle job.

Volume Batching of Concrete Ingredients

Volumetric batching of concrete does by using measurement boxes, locally referred to as "farmas" or gauge boxes. In a perfect case, the quantity of the farma is formed adequate to the load of 1 bag of cement, 35 liters, or multiple thereof.

Concrete ingredients like fine aggregates (sand), 10 mm Coarse aggregates, or 40mm Coarse aggregates (Kapachi) are measuring by farmas or gauge boxes that the farmas or gauge boxes are perfectly filled. In volumetric batching, water is measured either in Kg or liters. The meter uses to live the water quantity while batching or use cans of water having a hard and fast volume.

Weigh Batching of Concrete Ingredients

The proportion of concrete ingredients is set by the weighing (batching plant) in concretes weight batching. it's done either by using "weight batch" or by other equivalent weighing systems.

Weigh batching system facilitates simple, flexible, and accurate. On large projects, automatic batching plants usually install, which helps in achieving ultimate quality and consistency. Depending upon the sort of job, differing types of weight batches are available within the market. Manual weight batching, semi-automatic weigh batching, and fully automatic weigh batching (batching plant).

Water is an important constituent and hence using optimum water may be a must. Less water would make it concretely unworkable excess water will reduce the strength of concrete. Water must measure accurately in liters.

The choice of batching method depends on the dimensions of the work , production rate, and standards of batching performance.